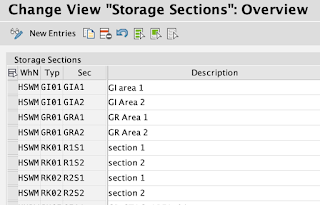

Storage Section and Storage Bins

Storage Section - This is a part of storage type and represents a group of bins with same characteristics. Commonly used storage sections are fast moving or slow moving items, etc. Storage section is optional. We have created below storage sections Storage Bins: are of 18 characters and unique across warehouse.To create storage bin, section is not mandatory. The Storage bins represent the physical location of storage space where the products are stored in Warehouse. They are at the lowest level of the organization structure and when you store an item in a Warehouse you need to mention its exact location. Define Storage bins Generate from Templates upload program To create storage bin, Mandatory fields are Warehouse no and storage type. Storage bin type : used to determine storage bin depending upon capacity and characteristics of storage bin. To differentiate the storage bins, we use this. Bin Access type :A resource type qualification. Each bin access type reflects a ...