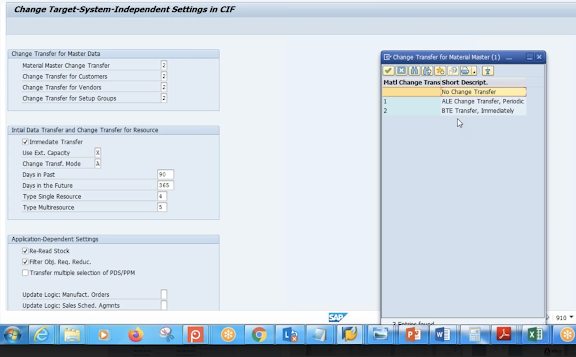

Material Master transfer from ECC to EWM

Whenever we transfer the material through CIF, its maintained as Global data in EWM. /SAPAPO/mat1 - maintain Product : Global Data level if we forgot to change or add the gross unit of measurement or any details which are present in ECC, then in case of decentralized we can update that data in EWM itself. How can we take up the material master change in ECC with the same data in case of decentralized? Material Master changes: To avoid data discrepancies, we need to transfer data from ERP to EWM system 1. Immediate transfer from ECC to EWM through BTE(Business transaction events) Integration with other sap components-> EWM->basic setting for data transfer->change transfer for master data -> configure change transfer for master data -> select BTE transfer (option 2) 2. Periodically Processing(Background jobs - ALE change pointers) 3. Also you can re-cif.. to transfer the updated data. /SCWM/MAT1 - Maintain warehouse product: Warehouse level